Labels for Metal

Custom Tags for the Metal Industry

Producers and processors of metal products face many different challenges in identifying their goods. Early product identification can significantly reduce waste, and streamline your process.

Products and Services

High-performance metal ID tags and labels designed for steel mills to identify and track metals during production, processing, and distribution.

Our rich history dates back over 80 years, when we first started working with mills in the heart of the UK’s steel city – Sheffield. You can overprint our labels and tags on-demand with our print solutions. Your labels can include barcodes, batch information, logos, and variable data. Our labels will adhere to scaley, oily, or finished products directly in-house.

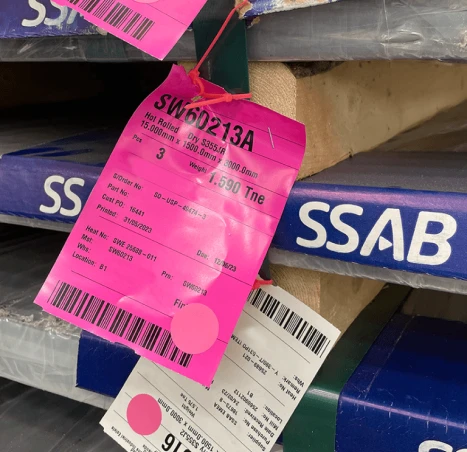

Tear Resistant Tags

Robust and durable tags are of the utmost importance when tracking metals. Our range of tear and rip-proof tags ensures your products can withstand the harshest conditions in the production and assembly lifecycle.

Whether you are a steel stockholder or steel manufacturer, Dura-ID Solutions has a range of high-performance tear resistant and rip proof tags that will ensure your steel gets from A to B, fully identified.

Just some of the tear resistant tags Dura-ID offer:

Industrial Self-Adhesives

Businesses face several common challenges when using industrial self-adhesives, such as:

- Labels falling off

- Attaching to uneven or rough surfaces

- Identifying oily or scaley product

- Label residue left on finished products

At Dura-ID Solutions, we leverage our years of practical experience and technical knowledge to help our clients overcome these obstacles. That’s why our products continue to be industry favourites. We offer a wide range of industrial self-adhesives:

High Temperature Labels

Identifying products at the earliest possible stage is crucial in the steel industry for stock or quality control. However, extremely high operating temperatures when labelling everything from slabs and ingots to flat sheet and wire rod coils make the process complex.

Here at Dura-ID Solutions, we have a range of tried and tested high-temperature tags and self-adhesive labels to help you overcome these challenges. Our range of high-temperature labels suit different temperature applications which our team of experts can advise on:

Print Your Own Labels

Print on demand and without delay with our range of plain or part-printed labels. With black-and-white or colour printing options, we have the ideal solution to help your business keep up with demand.

Zebra ZT510 for black and white printing including cast numbers, QR codes and further product information.

OKI C650 for full colour printing to include branding, colour coding, images and all of your other product information.

Dura-ID Solutions also supply the software to allow you to print your labels from a database of products. Our in-house technical team are always on hand to assist with support.

Tags for the Galvanising Process

Add important information to your steel products including barcodes or QR codes before galvanising, without the risk of losing vital info.

Thanks to the tags we offer, you can simplify product tracking within your factory in just a few simple steps. Print in-house, attach to the product, remove the laminate and it’s like new again. The use of our strong metal tags help to reduce the risk of misplacing valuable products and fines that could occur due to waste metal.

Our tags can be used in a range of processes –

- Fabricators

- Galvanisers

- Powder Coating

- Painting

- Shot blasting

Fixings and Stud Welding

Once your tagging solution has been designed and manufactured, you’ll need a reliable and sturdy fixing to ensure it remains in place. To help achieve this, we supply a range of fixings, including wires, clips, studs, pipe clips, and tube clips. Our expert team will advise on the best solution to attach to your product.

All of these fixings are straightforward to attach (even with gloves) and will ensure that your products remain traceable and identifiable throughout the entire product lifecycle.

If you are looking for something more permanent than fixings, ensure your labels stay tracked with our stud welding machines. Lightweight, portable, and easily assembled, this is an ideal solution for extra longevity.

News

Visit Us At Uk Metals Expo 2025

Did you know we can support fabricators and galvanisers?

Come and See Us at UK Metals Expo 2024

Moving Toward a Greener Future

Can we help you?

Carly Senior

Metals Sector Lead & Project Manager

Contact:

+44 (0)114 2612 214

csenior@dura-id.com

Alanah Betts

Export Account Manager

Contact:

+44 (0)114 2612 200

abetts@dura-id.com

You may be interested in

Can we help you?

If you have any questions about our products or services, just fill out this handy form and we will be right with you.